The supercapacitor is made from abundant, low-cost materials that can store large amounts of energy. The device could form the basis for inexpensive systems that store intermittent renewable energy, such as solar or wind power.

According to a new study, two of mankind’s most popular historical materials, cement and carbon black (which resembles very fine coal), could form the basis for a new low-cost energy storage system. The technology could facilitate the use of renewable energy sources such as solar, wind and tidal power, allowing energy networks to remain stable despite fluctuations in renewable energy supply.

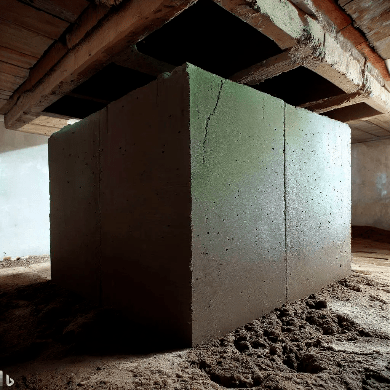

Researchers have found that the two materials can be combined with water to create a supercapacitor-an alternative to batteries-that could provide electricity storage. As an example, the MIT researchers who developed the system say their supercapacitor could be incorporated into the concrete foundation of a house, where it could store an entire day’s energy, adding little (or nothing) to the cost of the foundation and still providing the necessary structural strength. The researchers also envision a concrete roadway that could provide contactless charging for electric cars driving along it.

The simple but innovative technology is described in a forthcoming paper in the journal PNAS by MIT professors Franz-Josef Ulm, Admir Masic and Yang-Shao Horn and four other researchers from MIT and the Wyss Institute.

Capacitors are in principle very simple devices, consisting of two electrically conductive plates immersed in an electrolyte and separated by a membrane. When a voltage is applied to the capacitor, positively charged ions from the electrolyte accumulate on the negatively charged plate, while the positively charged plate accumulates negatively charged ions. Since the membrane between the plates blocks the migration of charged ions, this charge separation creates an electric field between the plates and the capacitor becomes charged. The two plates can hold this pair of charges for a period of time and then release them very quickly when needed. Supercapacitors are simply capacitors that can store exceptionally large charges.

The amount of energy a capacitor can store depends on the total area of its conducting plates. The key to the new supercapacitors developed by this team comes from a method of producing a cement-based material with an extremely large internal surface area, due to a dense interconnected network of conductive material within its volume.

The researchers achieved this by introducing carbon black-which is highly conductive-into a cement mixture along with cement powder and water, and allowing it to harden.

The water, reacting with the cement, naturally forms a branching network of openings within the structure, and carbon migrates into these spaces, creating wire-like structures within the hardened cement. These structures have a fractal structure, with larger branches sprouting smaller branches, and the latter sprouting even smaller branches, and so on, resulting in an extremely large surface area within the confines of a relatively small volume.

The material is then immersed in a standard electrolyte, such as potassium chloride, a very common salt that can be obtained from sea salt, which provides the charged particles that accumulate on the carbon structures. The researchers found that two electrodes made of this material, separated by a thin space or insulating layer, form a very powerful supercapacitor.

The two plates of the capacitor function like the two poles of a rechargeable battery of equivalent voltage: When they are connected to a source of electricity, as in the case of a battery, energy is stored in the plates, and then when they are connected to a load, electricity flows out again to provide power.

“The material is fascinating,” said researcher Admir Masic, “because it is the most widely used material in the world by humans, cement, combined with carbon black, which is a well-known historical material-the Dead Sea Scrolls were written with it. These are materials at least two millennia old that, when combined in a specific way, result in a conductive nanocomposite, and this is where things get really interesting.”

As the mixture solidifies and hardens, the researcher explains, “water is systematically consumed through cement hydration reactions, and this hydration fundamentally affects the carbon nanoparticles because they are hydrophobic (repel water).” As the mixture evolves, “the carbon black self-assembles into a connected strand.” The process is easily reproducible, with inexpensive materials readily available worldwide. In addition, the amount of carbon needed is very low-just 3 percent by volume of the mixture-to achieve a percolated carbon network, Masic explained.

The team calculated that a 45 cubic meter block of nanocarbon doped concrete, equivalent to a cube about 3.5 meters on a side – would have enough capacity to store about 10 kilowatt hours of energy, which is considered the average daily electricity consumption for a household. Because concrete would retain its strength, a house with a foundation made of this material could store energy produced for a day by solar panels or wind turbines and use it when needed. In addition, supercapacitors can be charged and discharged much more quickly than batteries, indeed the problem would be, if at all, moderating the discharge.

After a series of tests to determine the most effective ratios of cement, carbon black and water, the team demonstrated the process by making small supercapacitors, the size of some button batteries, about 1 centimeter in diameter and 1 millimeter thick, that could each be charged at 1 volt, like a 1-volt battery. They then connected three of these to demonstrate their ability to illuminate a 3-volt light-emitting diode (LED). Having demonstrated the principle, they now plan to build a series of larger versions, starting with those the size of a typical 12-volt car battery, and then moving up to a 45-cubic-meter version to demonstrate the ability to store as much energy as a house.

They found that there is a trade-off between the material’s storage capacity and its structural strength. By adding more carbon black, the resulting supercapacitor is able to store more energy, but the concrete is slightly weaker, and this could be useful for applications where the concrete does not play a structural role or where the full potential strength of the concrete is not required. For applications such as foundations or structural elements of a wind turbine base, the “strength” is about 10 percent carbon black in the mix.

Another potential application of carbon-cement supercapacitors is the construction of concrete roadways that could store energy produced by solar panels along the road and then supply it to electric vehicles driving along it, using the same kind of technology used for wirelessly rechargeable phones. A similar type of car charging system is already being developed by companies in Germany and the Netherlands, but it uses standard batteries for storage.

Early uses of this technology could be for isolated homes or buildings or shelters far from the power grid, which could be powered by solar panels connected to concrete supercapacitors, researchers say.

Ulm says the system is very scalable because the energy storage capacity is a direct function of the volume of the electrodes. “You can go from one-millimeter-thick electrodes to one-meter-thick electrodes, and by doing that you can scale the energy storage capacity from turning on an LED for a few seconds to powering an entire house,” he said.

Depending on the desired properties for a given application, the system could be fine-tuned by adjusting the mix. For a vehicle charging road, very fast charge and discharge rates would be needed, whereas to power a house “you have all day to charge it,” so a slower-charging material could be used, Ulm said. “So, it’s really a multifunctional material,” he added. In addition to the ability to store energy in the form of supercapacitors, the same type of concrete mixture can be used as a heating system by simply applying electricity to the concrete with carbon.This cement would enable a new vision of large-scale storage and energy transition without damaging the structures in which it is installed.

Leave a comment